What are Calipers?

Definition. Different sizes and types. Top manufacturers.

When to Use Calipers

Use cases. Using right tool for the task. Ensure tolerance and measurement uncertainty are adequately paired.

How to Use Calipers

Step 1 – Tool familiarization

Step 2 – Tool preparation

Step 3 – Object preparation

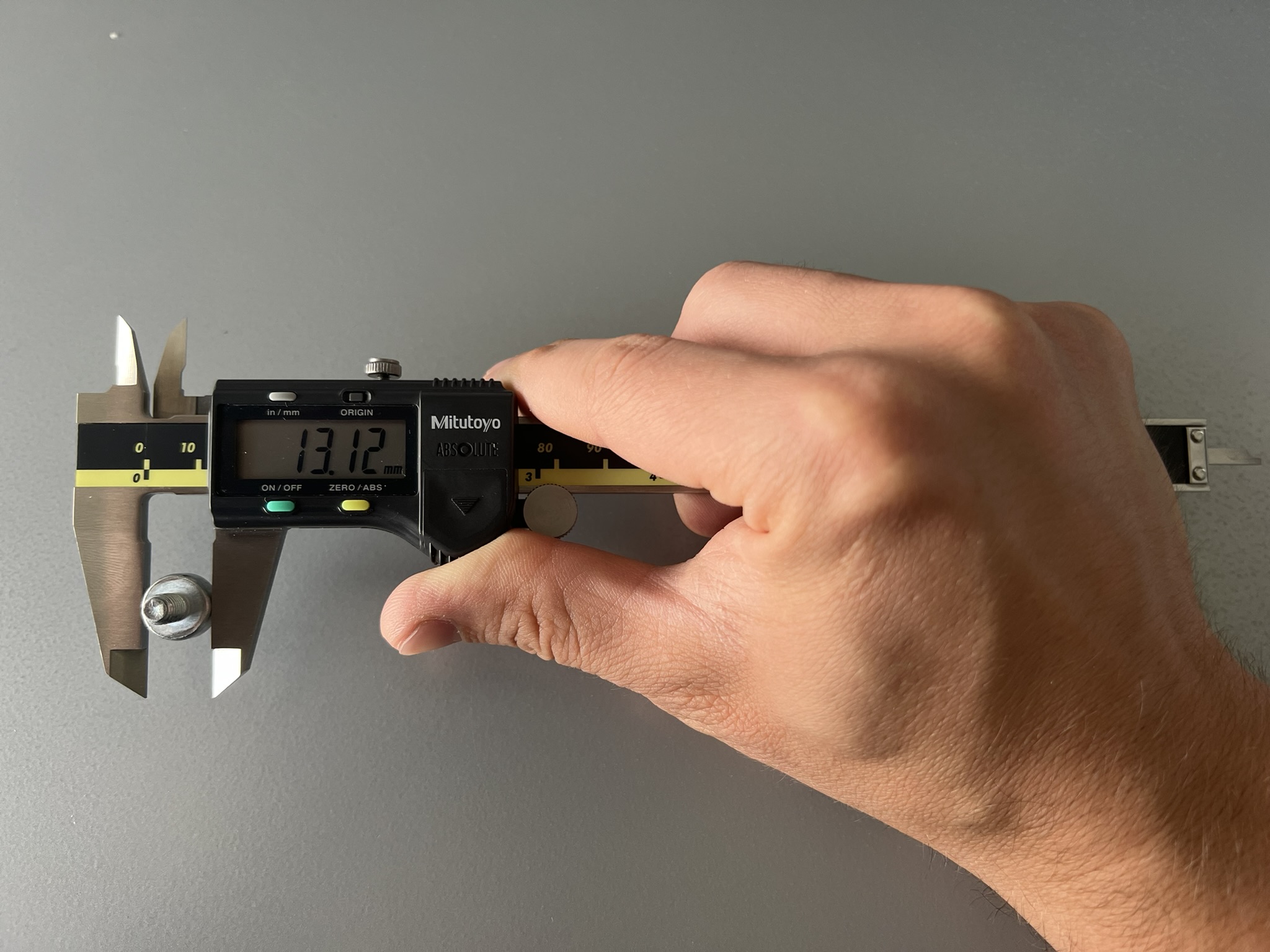

Step 4 – Measure feature on object (external, internal, depth)

Step 5 – Read measurement value (vernier, dial, digital)

Do’s and Don’t’s.

Caliper maintenance /storage

Safety considerations

What Are the Benefits of Using Calipers?

- Reasonable measurement accuracy and precision

- Versatility

- Affordability/Availability

What Are the Drawbacks of Using Calipers?

- Operator Skill – Calipers are very reliable and simple to use tools. However, they are highly sensitive to operator miss-use. Incorrect handling and maintenance can result in widely varying measurement results. Proper training and following the steps above will ensure success in your next GR&R study.

- Limited Accuracy – Calipers are often a great choice for simple hand measurements in a shop floor-like environment but are inherently less accurate (only accurate to 0.001-0.005″) than some other handy measurement tools. For example, micrometers are a better alternative for similar outer diameter measurements due to their design and construction (see Abbe’s principle below).

- Size – One very small drawback of using calipers is their limited size. Calipers are usually sized at 6″ but also commonly come in 12″ configurations with very few sized even larger still. A vast majority of hand measurements with calipers will fall into the 0-12″ range. As measurement get larger, other tools are better utilized due to the potentially increasing unwieldy size. Calipers are simple and easy to use but are best fit within a limited size window.

- Measurement Error – See section below.

What Are Potential Causes of Caliper Measurement Error?

- Parallax Error – Parallax error is a common source of measurement error on any instrument with a dial indicator readout. This error results from viewing an indicator and scale (such as a needle on the face of a dial indicator) from an side angle. If not viewed directly perpendicular to the readout the space between the needle and scale on the face creates a visual discrepancy known as parallax error.

- Zero Error – Zero error is another common source of measurement error not limited to calipers. Any time that the visual readout does not show the zero mark when the caliper jaws are closed, there is an amount of zero error contributing additional uncertainty to the measurement. Usually an indicator (dial or digital) can be adjusted back to zero position with the jaws closed to remove this error.

- Abbe’s Principle – Abbe’s principle says that the axis of the target measurement should align with the axis of the measuring instrument in order to obtain the most accurate measurement result for a given measurement system. From this principle, calipers inherently have some amount of error built in due to the points of measurement on the jaws are offset from the axis of measurement in the body of the caliper (for this reason, calipers cannot be more accurate than micrometers). Alignment of the jaws are critical to accurate measurements on a caliper due to this principle. To avoid additional source of this error, check for gaps in the jaws from misalignment when the jaws are completely closed at the zero position and try to measure the object as close to the rail as possible.

- Excessive Force – Excessive force can contribute to measurement error through damage and deformation of the tool and bending the jaws relative to the measurement rail. Too much force closing the jaws can damage how the jaws interact with the rail of the tool. This can lead to accuracy (measurements are biased) and precision (measurements are not repeatable). If the jaws become deformed relative to the rail, refer back to Abbe’s principle.

References and Further Reading

- https://www.mitutoyo.com/metrology-insights/mitutoyo-calipers-digital-dial-and-vernier-calipers-precision-measurement-tools-for-manufacturing/

- https://www2.mitutoyo.co.jp/eng/useful/E11003/pdf/23.pdf

- https://www.keyence.co.in/ss/products/measure-sys/measurement-selection/basic/abbe-principle.jsp#:~:text=This%20principle%20states%20that%2C%20%22In,fashion%20in%20the%20measurement%20direction.%22